Automation protocols ensure stable and secure performance

EtherNet/IP & TCP/IP

Standard networks enabling fast and real-time industrial device communication

PROFINET

Industrial Ethernet protocol ensuring deterministic, high-speed automation control

Modbus TCP/RTU

Simple, reliable protocol connecting sensors, controllers, and industrial devices

BACnet/IP

Protocol for building automation, integrating HVAC, lighting, and industrial systems

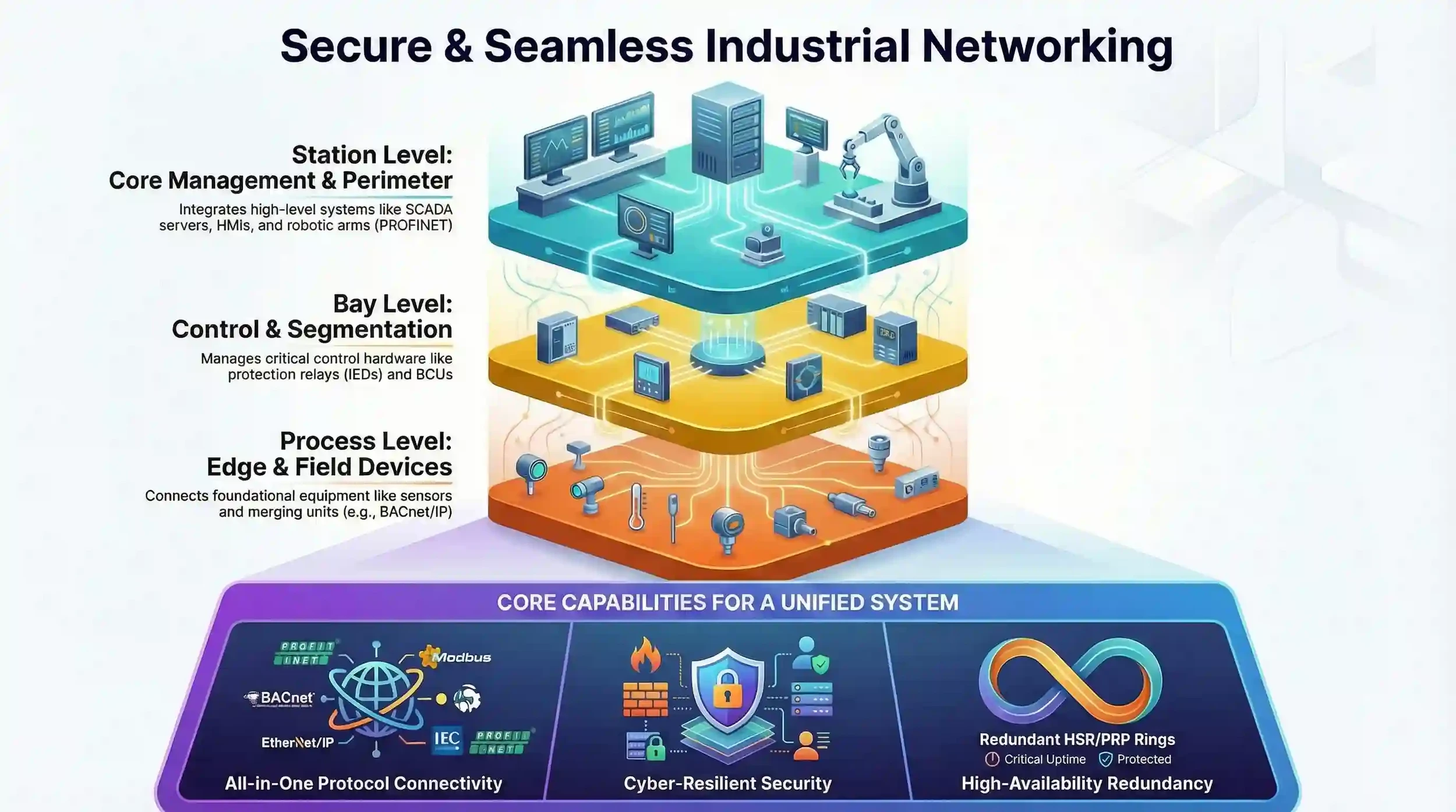

Before industrial switches can effectively support automation protocols, several challenges must be addressed. Network design must balance real-time determinism with standard Ethernet traffic, ensuring low latency and predictable delivery for control data. Protocol diversity adds complexity, as EtherNet/IP, PROFINET, Modbus, and BACnet impose different timing, priority, and topology requirements. Hardware resilience is critical, since switches operate in environments with extreme temperatures, vibration, and electromagnetic interference. Cybersecurity must be built in from the start to protect operational technology networks from unauthorized access, malware, and misconfiguration.

Integration with legacy equipment presents additional obstacles, requiring support for older standards, serial communication, and gradual migration paths. Scalability and manageability also matter, as growing automation systems demand centralized monitoring, simplified configuration, and minimal downtime during expansion. Finally, compliance with industrial standards and certifications is necessary to ensure safety, interoperability, and long-term reliability across diverse automation applications. These issues must be resolved before deployment to avoid operational risk and performance degradation in complex industrial environments globally.

Our Solution

Industrial managed switches with support for automation protocols, such as EtherNet/IP, PROFINET, Modbus TCP/RTU, and BACnet/IP, offer significant advantages in modern industrial networks. By enabling real-time communication between controllers, sensors, and actuators, these switches ensure high reliability and low latency, which are critical for automated production processes. Managed features, such as VLAN segmentation, QoS, and redundant ring topologies, improve network stability and reduce downtime, even in harsh environments.

Security capabilities, including ACLs and IEC 62443 compliance, protect critical operational technology (OT) from cyber threats. Furthermore, protocol-aware switches simplify integration across heterogeneous devices, allowing seamless data exchange and interoperability between different automation systems. With enhanced monitoring and diagnostics, operators can proactively identify and resolve issues, optimize performance, and support Industry 4.0 initiatives, making industrial managed switches a cornerstone for efficient, resilient, and secure automated networks.

Recommended Products

-4X/imgs/poe_front__sm.webp)

DTS-8G(P)-4X

Industrial 8G+4x10G TSN Managed PoE Switch

-6X/imgs/poe_front__sm.webp)

DTS-16G(P)-6X

Industrial 16G+6x10G TSN Managed PoE Switch

-8M(P)-6X/imgs/poe_front__sm.webp)

DTS-8G(P)-8M(P)-6X

Industrial 8G+8x2.5G+6x10G TSN Managed PoE Switch

-4X/imgs/nopoe_front__sm.webp)

RTS-8G(P)-4X

Industrial 8G+4x10G TSN Managed PoE Switch

-8M(P)-6X/imgs/poe_front__sm.webp)

RTS-8G(P)-8M(P)-6X

Industrial 8G+8x2.5G+6x10G TSN Managed PoE Switch

-6X/imgs/poe_front__sm.webp)

RTS-16G(P)-6X

Industrial 16G+6x10G TSN Managed PoE Switch

-6X/imgs/poe_front__sm.webp)

RTS-24G(P)-6X

Industrial 24G+6x10G TSN Managed PoE Switch