Intrising Switches Adopted in Existing PRP Topology

How Intrising Helps Customer to Scale up Network While Keeping Compatibility of Existing Equipment

| Location | Taiwan |

|---|---|

| Industry | Networking and Industrial Automation |

| Application | Smart Factory Network |

Case Background

PRP (Parallel Redundancy Protocol) is considered one of the most important technologies in networking. By having PRP in the network, it provides fault tolerance and the highest possible availability by providing interruption-free switchovers.

The existing network that our client has consists of devices that can support PRP and those that can’t. This leads to an issue because it makes communication between devices impossible to happen. Another reason why our client must implement PRP is that due to the location of the network which is in a plant, it’s important to have zero-recovery time in case of critical conditions.

Facing this particular issue, our client tried to reach out to other companies first before deciding to bring this issue to Intrising. But, the other companies’ solutions are not something that they are keen on as they have to discard the devices that can’t support PRP to implement the solution. They perceive the devices as still necessary to be part of the network, therefore discarding them is not the option they have in mind.

Eventually, the client came to Intrising and stressed that they do not want any devices to be discarded. Intrising assure none of the devices will be discarded and the performance of the network will be improved with the implementation of PRP.

Requirements

- PRP implementation for smooth communication between the devices within the network without having to discard old devices.

- Zero recovery time makes communication is not interrupted and there is no frame loss when there is a network failure. As a result, devices can be connected and disconnected without interrupting the operation of the network or other devices.

- Compatible across platforms as devices in the network have different OS such as Windows, Linux, RTOS, etc.

Solution Provided by Us

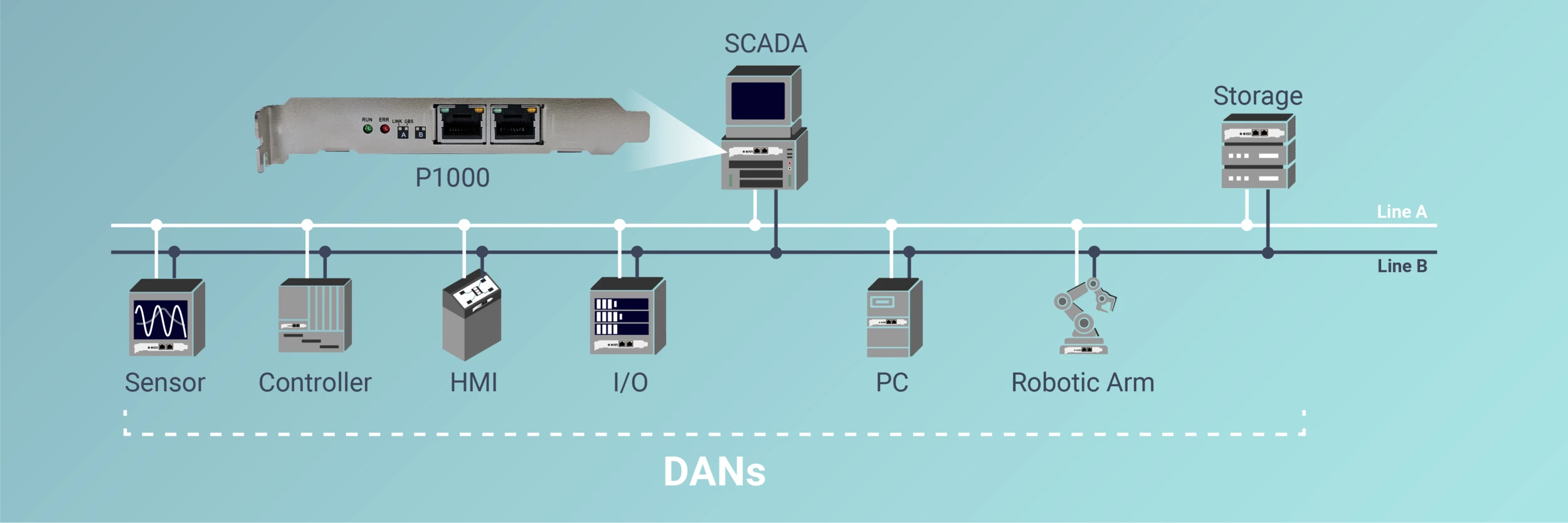

Based on the client’s requirements, Intrising creates Ethernet Redundant PCI-E Module which later we refer to as P1000. P1000 supports PRP, so by deploying it into the client’s device that can’t support PRP before, the device can now implement PRP. The result of this is that communication between devices is possible now because they all can connect to the PRP network. The deployment of P1000 is also easy, it’s only plug and play. The client also can keep the devices even though they are considered old based on the specifications. This makes the client becomes very pleased with the solution.

In addition to that, P1000 also supports IEC 61850 MMS (Manufacturing Message Specification). This is a client/server-based protocol for communication over Ethernet between IEDs (Intelligent Electronic Devices), which are lower-level entities, and higher-level entities (like RTUs and SCADAs). With this protocol, the SCADA system can make communication between field devices possible so the client can monitor the power quality in real time. By using the SCADA system, the client can achieve unparalleled excellence in optimizing and future-proofing the network. Our P1000 can be monitored with the SCADA system. SCADA and PRP come hand in hand because it's advised to use PRP when performing crucial tasks on a SCADA system to get the rapid network failover times required. Due to its usage, PRP also offers advantages in terms of maintenance and operation, making it advantageous for solutions that demand high availability. With P1000, the performance of the network improves significantly.

Why P1000

- Compatible with the client’s devices, so there is no need to replace the existing devices. This reduces the deployment cost.

- There is no specific software requirement required as it can be used across platforms. Installment becomes so much easier.

- Gives way better sense of security and protection with the zero-recovery time that helps the network in case an emergency occurs.